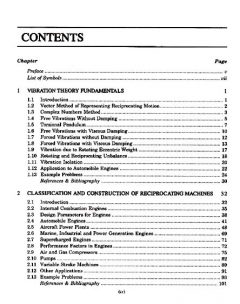

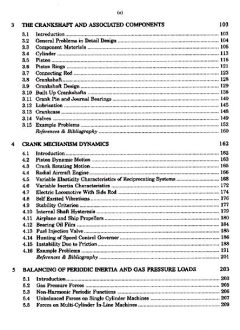

This book primarily written to meet the needs of practicing engineers in a large variety of industries where reciprocating machines are used, although all of the material is suitable for college undergraduate level design engineering courses. It is expected that the reader is familiar with basic to medium level calculus offered at the college undergraduate level. The first chapter of the book deals with classical vibration theory, starting with a single degree of freedom system, to develop concepts of damping, response and unbalance. The second chapter deals with types and classification of reciprocating machines, while the third chapter discusses detail-design aspects of machine components. The fourth chapter introduces the dynamics of slider and crank mechanism, and provides explanation of the purpose and motion of various components. The fifth chapter looks into dynamic forces created in the system, and methods to motion of various components. The fifth chapter looks into dynamic forces created in the system, and methods to balance gas pressure and inertia loads. The sixth chapter explains the torsional vibration theory and looks at the different variables associated with it. Chapter seven analyzes flexural vibrations and lateral critical speed concepts, together with journal bearings and their impact on a rotating system. Advanced analytical techniques to determine dynamic characteristics of all major components of reciprocating machinery are presented in chapter eight. Methods to mitigate torsional vibrations in a crankshaft using absorbers are analyzed in close detail. Various mechanisms of flexural excitation sources and their response on a rotor-bearing system are explored. Stability of a rotor and different destabilizing mechanisms are also included in this chapter. Techniques in vibration measurement and balancing of reciprocating and rotating systems are presented in chapter nine. Chapter ten looks at computational fluid dynamics aspects of flow through intake and exhaust manifolds, as well as fluid flow induced component vibrations. Chapter eleven extends this discussion to pressure pulsations in piping attached to reciprocating pumps and compressors. Chapter twelve considers the interaction between the structural dynamics of components and noise, together with methods to improve sound quality. Optimized design of components of reciprocating machinery for specified parameters and set target values is investigated at length in chapter thirteen. Practicing engineers interested in applying the theoretical model to their own operating system will find case histories shown in chapter fourteen useful. Computer programs provide complete methods in evaluating the performance of components and system. Electronic spreadsheet type of calculations are shown here to consider several aspects of the overall problem. Program modules are arranged to calculate the full array of design parameters, dimensions and dynamic characteristics. As a further guide, actual example problems using the program modules are provided within the programs as well as in the text. Using a step-by-step procedure, a complete dynamic behavior and response of a system can be obtained through these program modules, thus providing the reader with a full design of the system to satisfy a given set of requirements. A suite of program sub-routines for dynamic balancing of rotating systems in the shop or in the field is also included.

Reciprocating Machinery Dynamics

In stock

Free & Quick Delivery Worldwide

reviews

Bibliographic information

Title

Reciprocating Machinery Dynamics

Author

Edition

1st ed.

Publisher

ISBN

8122418139, 9788122418132

Length

xiv+531p., Figures; Tables; References; Bibliography; 25cm.

Subjects

There are no reviews yet.